Burnished Tubes

Description

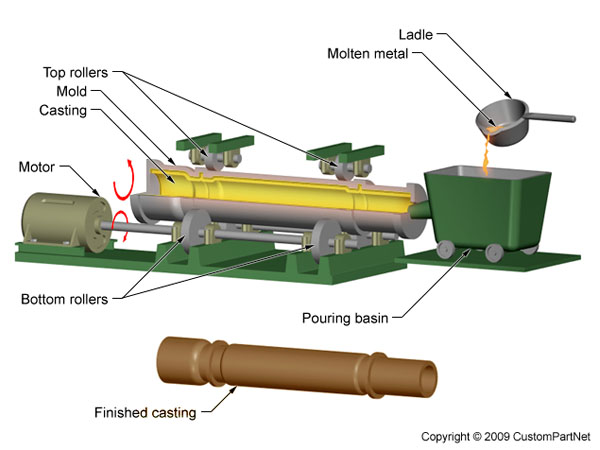

DHT is involved the manufacturing of Burnished Tubes for our respected clients. These Tubes are designed using latest technology and advanced machines so as to ensure their adherence with set industry standards and norms. The Cold drawn Tubes offered by us are acclaimed in the market for their high performance, low maintenance and longer functional life.

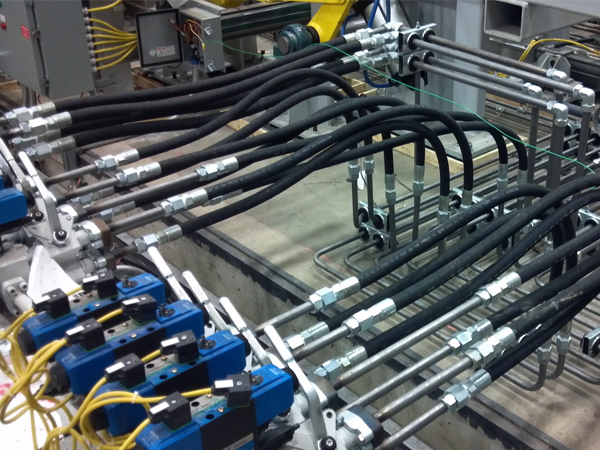

Skiving and roller burnishing steel tubes made mainly for the hydraulic cylinder industry and other applications where fine-finishing of the internal diameter of a tube is required, Primarily for hydraulics in the contracting, mining and construction industries.

Besides, we also provide the ready for assembling cylinder tube, we can have the tube processed as per your drawing, for example, the tube fully machined and welded with flange or oil port or other necessary parts as it's required.

Dimensions :

Inside diameter :between 25-300 mm

Outside diameter : according EN 10305-1(DIN 2391)

Steel grades :

E355 +SR (St 52 BK+S)

E410 +SR (St E460 BK+S)

Roundness : max IT

Processed surface roughness :

max Ra=0,6 µm (normally in the range 0,30-0,40 µm) for honed surface

max Ra=0,3 µm (normally in the range 0.15-0.22 µm) for skived and roller burnished surface

Straightness :

Local deviation : max. 1 mm per each meter of length

Total deviation : for tubes with length less than 6 m - max. 3.5 mm for tubes with length bigger than 6 m, the deviation shall be increased by 0.5 mm for each meter over 6 m

BENEFITS

- Durable

- Dimensionally accurate

- Temperature resistant, etc

-

The tubes are continuously marked with the following

text: "PRODUCER / Steel grade / EN 10305-1 / ODxID /

HEAT number" -

The tubes are inside and outside protected with oil in

order to assure the temporary protection against

corrosion.

APPLICATIONS

- Fine-finishing of the internal diameter

- Primarily for hydraulics in the contracting

- Mining and construction industries.

- Skiving has some preference over honing

-

Skiving can increase the tube ID surface hardness

obviously - Providing better tolerance and better surface finishing

USED IN INDUSTRIES

- Reduced machine time and Minimal waste.

- Manufacturing Industry

- Aeronautical Industry

- Auto Industry

- Chemical Industry

- Drugs

- Food & Beverages

- Mining

.jpg)